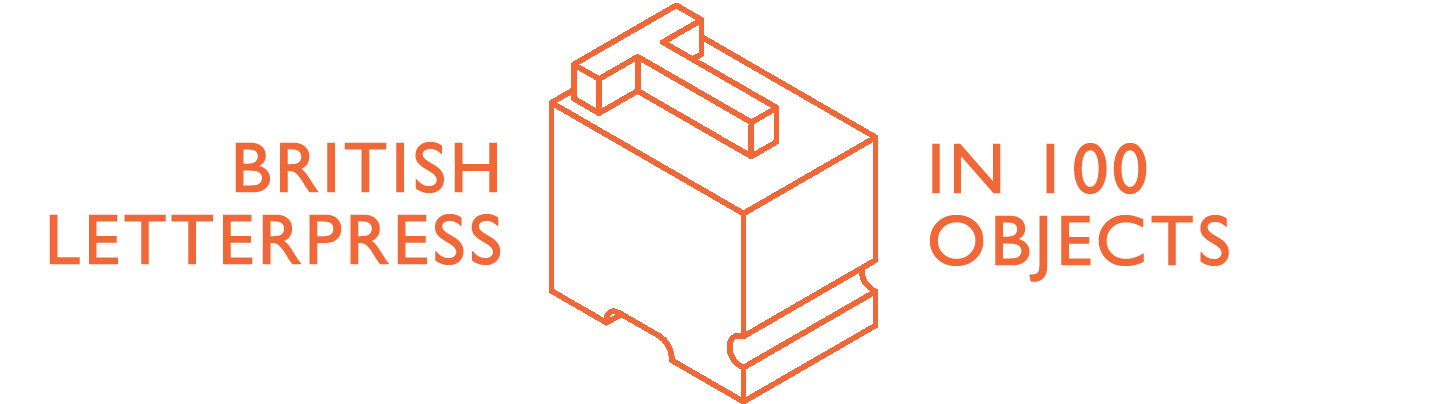

While the Vandercook is coveted for precision printing in both the UK and the USA, a British firm made smaller, solid and versatile presses. Farley Engineering (Croydon) Ltd made a selection of presses of different sizes and sophistication.

They are a remarkably low-profile firm. I can find reference to a March 1944 court case brought by HM Inspector of Factories where a worker lost a finger in a horizonal milling machine. Accepted in partial mitigation was that the works had been ‘almost entirely destroyed by enemy action’ in February of the same year. So, we can take that Farley was in operation at least during World War II.

The July and August 1950 British Printer refers to Farley including one of other their presses in a motor-coach that had been equipped as a sales vehicle to tour the Netherlands in order to sell to the Dutch despite their affinity for German equipment.

New Proofing Presses

The most detailed account of new presses is found in the July 1963 British Printer, where they launched two presses — the No. 16 and No. 24, and I’ve summarised below their specifications.

| No. 16 | No. 24 | |

| Bed Size | 20½″ × 28″ | 20½″ × 26″ |

| Printing Area | 20″ × 28″ 20″ × 26¾″ when fitted with grippers | 20″ × 16″ with automatic grippers |

| Floor Space Required | 2′ 1″ × 4′ 7″ | 2′ 9″ × 4′ 2″ |

Both presses include the Farley Patented Drive. It appears that in 1957 Farley was awarded a patent authored by Leonard Harding, in which an eccentric within the main impression roller could be used to adjust the height between the bed of the press and the impression roller. While this sounds like a small indulgence, it allowed printers to proof from type on galleys, directly from the bed or use foreign types of different types through a simple adjustment.

After the Mid 1960s

The British Printer for April 1968 says that the firm will exhibit their new self-inking electric galley press.

Richard Small has shared a wonderful 1971 catalogue showing the firm’s wares

Exploiting the Adjustable Cylinder

In the 1989 issue of Matrix, Mark Arman in the article A Collection of Printers’ Flowers describes how the Farley’s adjustable cylinder is exploited for two colour runs at the Workshop Press.

The chase is locked into the bed of the press and then the quoins holding the forme are loosened. The types to be printed in a second colour are carefully removed and 3-point leads, cut to size, are inserted in their places: the types are then replaced and the forme is locked up again with these types standing 3 points proud of their fellows. Since the Farley 24 provides for the height of the inking rollers to be set automatically with the impression cylinder, and both are adjustable by calibrated drum, the height is then adjusted so that the second colour is printed. At the end of the run the types used are removed and replaced with quads and spaces, the height of the cylinder and inking rollers is returned to normal and printing the main colour can proceed. This method is particularly suitable for printing complex fleuron combinations in two colours, but it is only possible using a proofing press with micro-adjustment and automatic inking.

Arman, Mark. (1989). A Collection of Printers’ Flowers in Matrix 9.

Year and Era

1963 / Commercial

Based on introduction of this model, British Printer article, July 1963

Object Type

Press

Location

Gladstone Road, East Croydon, Surrey

Sources and More Information

- Norwood News – Friday 14 July 1944

- Richard Small’s site

An Appeal

If you have something linked to this object, please get in touch.