Origins of Manufactured Woodletter

Wood was probably the first material used to create printing surfaces. In the movable type era, wood templates were impressed in sand, and filled with hot metal to create the largest letters needed by printers. English letter foundries were offering up to 18 line (3″) types cast in this way, but the characters were heavy and prone to break. Individual letters could be cut by hand in wood, but this was a very slow and expensive process.

The invention of the router for cutting woodletter in the US opened up the possibility of standard faces, cut in multiple sizes a lot more quickly than had been possible earlier. The materials were less expensive and the finished product had a better and more even surface than metal equivalents. In 1828, Darius Wells of New York issued the first catalogue of woodletter.

The first UK woodletter maker looks to be Eglington of London, supplier to the Caslon Letter Foundry around 1870.

DeLittle in the UK

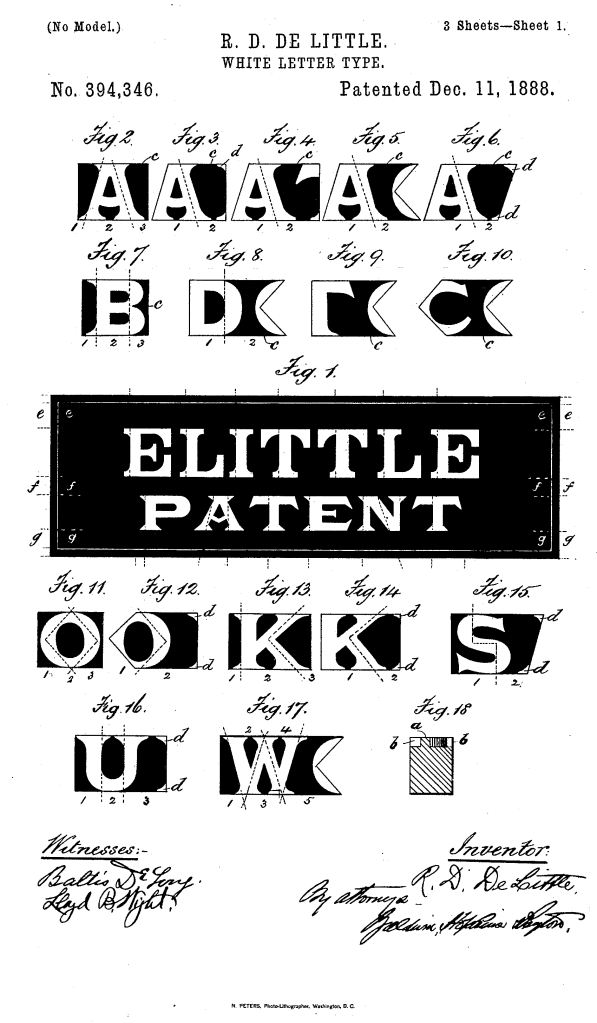

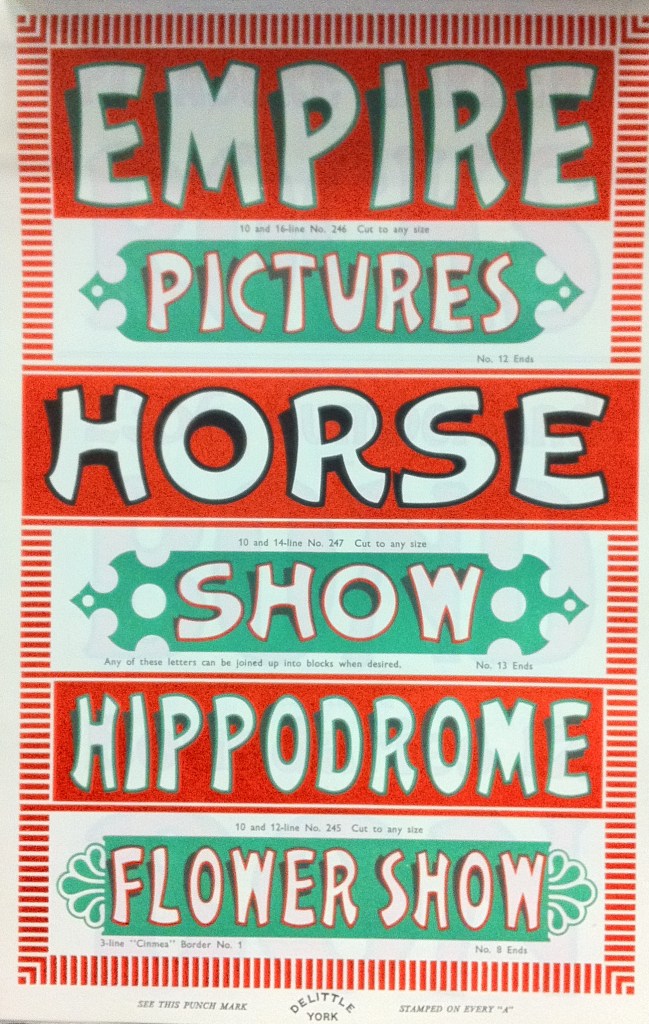

Robert Duncan DeLittle was born in York in April 1868. While working in Adelaide, Australia between 1885 and 1887, he developed a new way of cutting ‘white letter’. This is a specialised form of woodletter creating a banner effect where the letters are white against a printed background. The problem with white letter was that the joins in each character had a tendency to show because the joins followed the edge of each letter. DeLittle’s innovation was to move the joins to within the white space. This made the assembly more complex, because now different components were needed for each combination of letters (like a U and an M) rather than for each letter. That said, the result was much neater.

In June 1888 Robert returned to the UK and took premises near his father’s printing works to manufacture his white letter in York. His first order, in February 1889 was sent back to F T Wimble in Australia. Much of his 1889 custom was selling to other printers’ suppliers in the UK and some for another woodletter manufacturer, Day & Collins.

In June 1889, Robert bought stocks of hardwood — birch and sycamore — and printed the first specimen sheets a month later.

As the business grew, Robert became aware that the focus on white letter might be supplemented with more ‘usual’ styles of woodletter. Some more usual types were created, references № 51, 52 and 53 in 1892.

In 1899 the firm moved to their purpose-built factory at Vine Street in York.

By 1900 the firm offered 42 faces. DeLittle never employed their own sales force: selling either though agents who were paid on commission or through other printers’ suppliers.

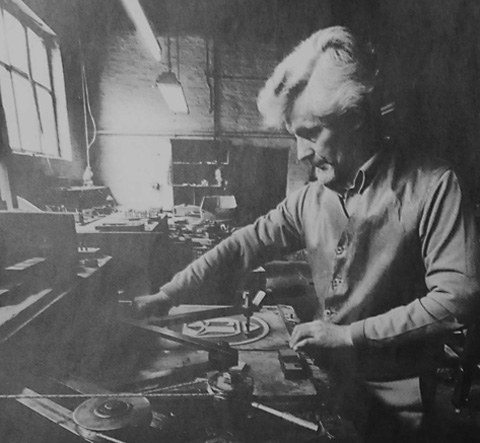

By the 1980s, DeLittle became Britain’s only woodletter maker, the firm being run by Jim DeLittle, Robert’s grandson. By this point DeLittle was offering 300 faces, including in multiple scripts.

With no-one able to carry on the business, DeLittle’s closed. The machinery, including pantographs and the patterns for each face went to the Type Museum in London in 1996.

Jim DeLittle passed away in 2014.

The Woodletter Business

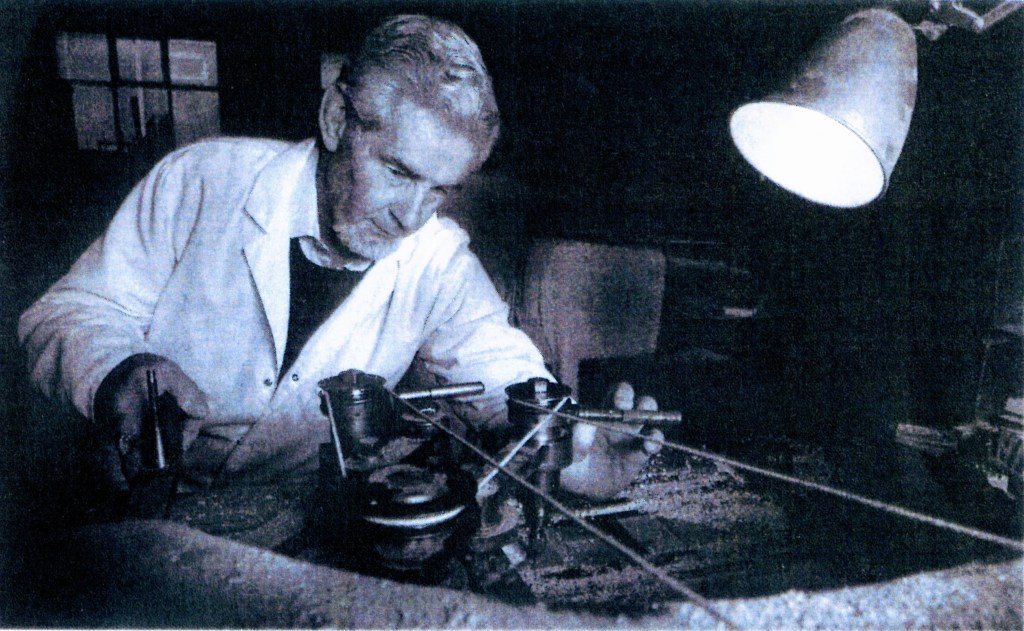

The process of going from design to woodletter is painstaking. Drawings are developed, and from these wooden templates. Templates are ‘masters’ and a pantograph is used to scale these up or down accordingly. At their early premises, DeLittle had a fireproof room likely to store these templates.

Early wood purchases were birch and sycamore. By the 1980s French hornbeam or Canadian maple were being used. The wood was cut to 1¼″ thick sheets and allowed to mature for five years. One face of the wood was finished to take the cutting of the character.

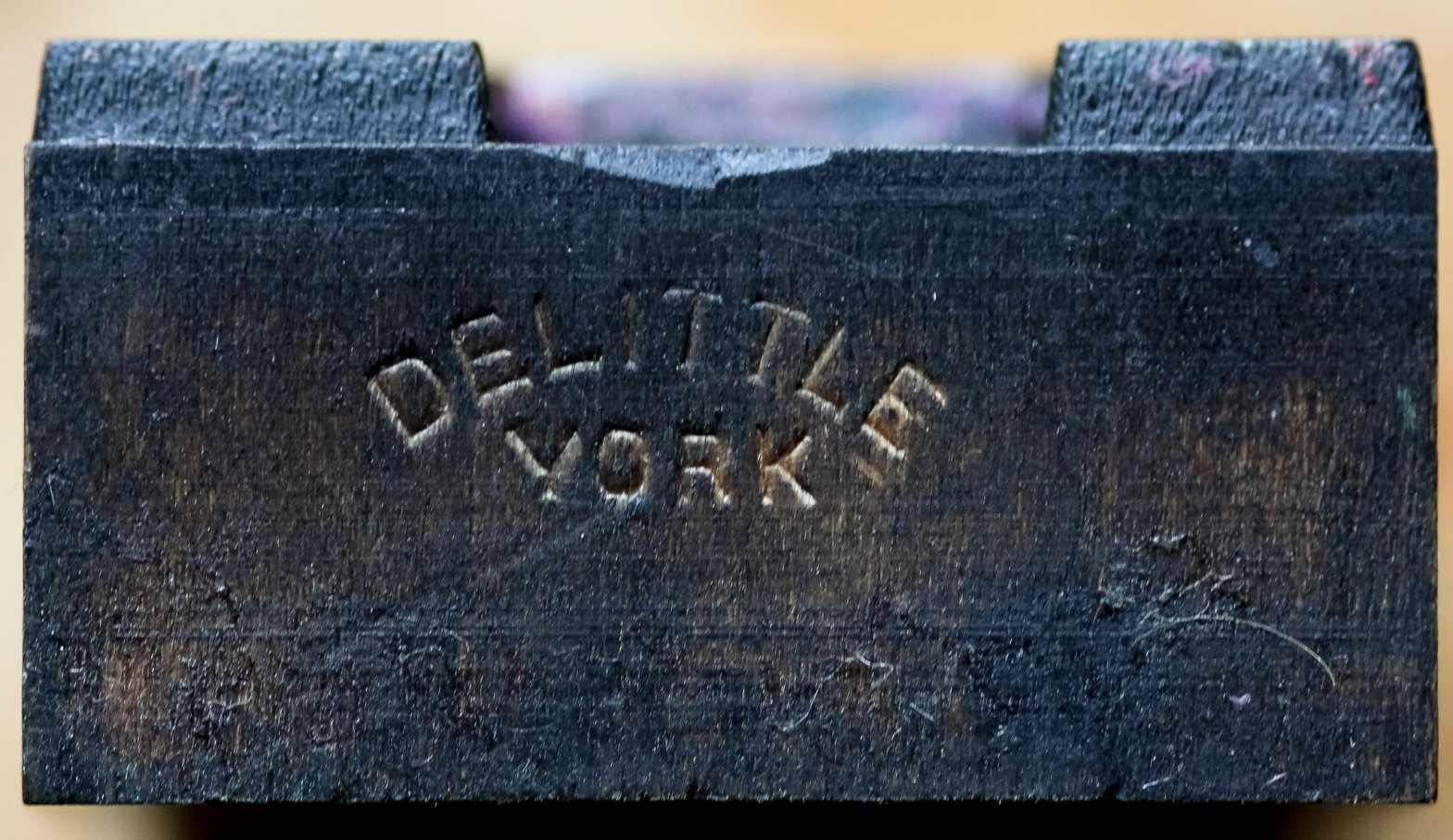

The combination of the template, the pantograph and the carving of wood gives a basic character. This has to be planed to type-high and then finished by hand, for example, to carve out or deepen the counters. This is then soaked in linseed oil, and proofed on an Albion press using carbon paper to avoid inking the type. The makers mark is applied to the “A” character of each fount.

Type was sold in ‘dozens’, and character height is expressed in lines, one line equal to 12pt. DeLittle manufactured types from 1 line (12pt) to 180 line (2′6″).

Specimen books were produced by printing sheets of specimens and assembling these periodically in to books. This makes dating books especially difficult as a single book issued in, say, 1950 might include specimen sheets dating from the 1930s as well as more modern faces. An example specimen book is available through type.org.uk.

Perspex-Faced Woodletter

Example here from friends at St Bride Library:

Woodletter Makers Today

While DeLittle’s collection currently is hosted by the under-threat Type Museum in London, there are modern UK makers of woodletter. I can happily vouch for each!

Year and Era

1888 / Mass Production

Object Type

Types and Casting

Location

Vine Street, York as the manufactory for Delittle.

Sources and More Information

- British Printing Society, Small Printer branch report 1988

- Varney, Jim, Last of His Type from Dalesman magazine

- Bolton, Claire, DeLittle, 1888-1988, 1988

- Bolton, Claire, DeLittle: An English Woodletter Manufacturer, 1981

- Kelly, Rob Roy, American Wood Type 1828-1900

An Appeal

If you have something linked to this object, please get in touch.

Header Image: “Marque Delittle York” flickr photo by Ampersand Press Lab https://flickr.com/photos/ampersandpresslab/32993285306 shared under a Creative Commons (BY-NC) license