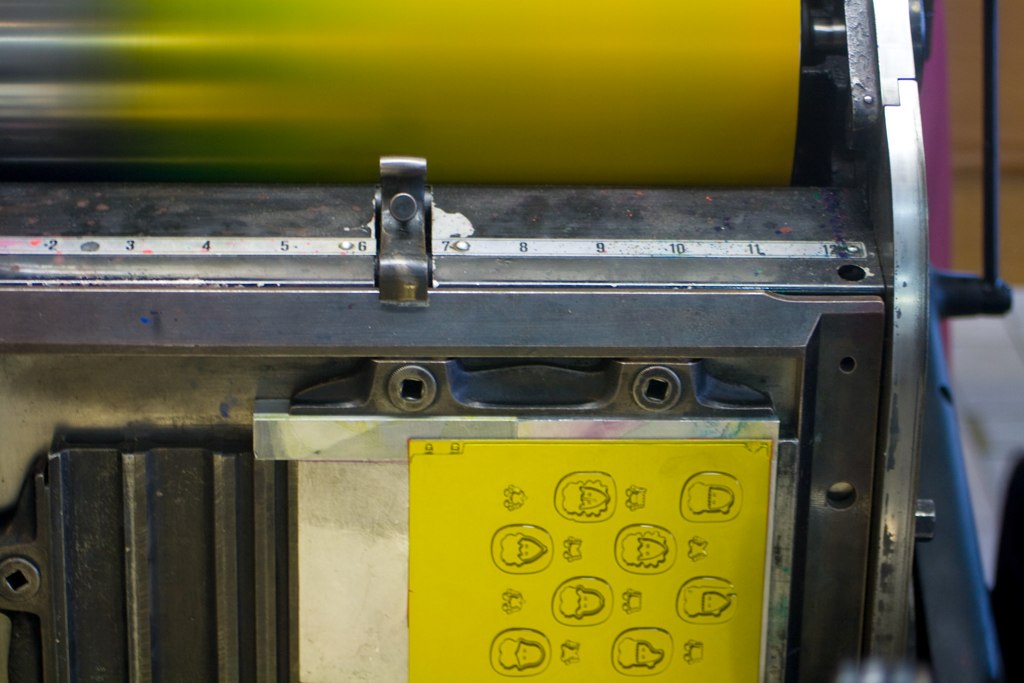

Letterpress printers have always needed a relief surface from which to print. This would have initially been carved wooden blocks, then lead type. The principles behind photopolymer are still designed to give us that relief surface but use a combination of light and special materials to create the printing surface.

The process takes a previously soluble surface and makes this hard and insoluble through the action of light. Essentially, where UV light is cast on the plate, this firms up, and the remainder can be washed off.

The idea of light reacting with a surface has been around a long time. The key difficulty in photopolymer printing is to make sure that the printing surface and withstand the pressures that come with letterpress printing.

Background

1955 seems to the point at which the process was first demonstrated in the UK. The British Printer reports that the Collobloc process had been demonstrated at IPEX by Photogravure & Allied Holdings Ltd Group, and had been covered in the 1955 Penrose Annual.

The original process involved a laminated foil, with the photopolymer material. This had to be sensitised before being exposed to a camera. After exposure this material had to be put through a mangle to join another material before curing. The process, it was claimed, could be mastered with just ‘two to three months’ of basic training. Interestingly a ‘screen’ was used between camera and plate and this itself, along with the mix of polymer, were patented.

You can view the original 1953 patent online.

‘Photopolymer’

By 1958 there were three new proposals to use a similar technique: the Time-Life nylon plate; the Fogra nylon-plate; and the Du Pont plate. These together were called photopolymer.

Each of these used slightly different combinations of materials but the overall approach was the same — using light to harden part of the surface and washing the remainder away.

Concerns at the time included the ability to correct or adjust the plates once made, the durability of the material, and whether colour plates — normally requiring immense precision — could be made. In fact the Collobloc plates had been used to show what their polymer plates with no hand-correction were capable of.

The British Printer ended their 1958 article with —

Only the future will show whether or not there is room for both metal and polymers in letter-press printing.

British Printer, 1958

Photopolymer Today

Just as the possibilities of using photopolymer were in the ascendancy, the use of letterpress overall was giving way to litho printing. Photopolymer carried on, even Ludlow made their own set-up to create photopolymer plates.

In the early 2000s, with an influx of new printers, keen to see a letterpress effect (typically debossed), and with a press but not always the type, attention turned to using photopolymer plates as a way of preserving the craft while opening up new layouts and not needing the same level of skill to start.

Today’s bible for using photopolymer in the letterpress process is Printing Digital Type on the Hand-Operated Flatbed Cylinder Press by Gerald Lange; and there’s an amazing Letterpress Commons guide to the process.

The debate continues to rage about the role of this type of printing versus the traditional letterpress approach. In fairness there’s probably a place for photopolymer in letterpress, perhaps where hand-setting is impossible, or the desired effect would lead to damaging lead types.

Polymer Set Ups

To take advantage of this renewed interest, firms began to offer the components of photopolymer as components that would work together — typically a metal, magnetic base on to which would be applied a metal-backed polymer plate. This means you can email a design, and take delivery of the slim plate only — positioning and applying on to the base you re-use. In the US, Boxcar is the most popular of these. Here in the UK, friends at Lyme Bay Press offer a similar service.

Year and Era

1953 (February 27, patent granted) / Modern

Object Type

Types and Casting (as a printing surface)

Location

Patentee’s Address: Cologne, Germany

Sources and More Information

- British Printer, 1955 and 1958

- UK Patent as linked above

An Appeal

If you have something linked to this object, please get in touch.

“EggHeads Print1” flickr photo by _ SpaceFrog _ https://flickr.com/photos/37117402@N03/3418829053 shared under a Creative Commons (BY-NC) license