Many UK printers still swear by their ‘Windmills’: Heidelberg machines that automatically pick up paper from a stack and take an impression from the platen. Most shops use them today for numbering, creasing and perforating.

Before this machine was ubiquitous, there was a British contender — The Thompson-British Auto Platen. Having spoken to a few users and owners of these machines, they always have a preference for the Thompson. Let’s have a look at this under-appreciated press and dig a little deeper in to what made it unique.

Thompson’s were a long-standing printers engineer in Manchester. The photo below shows their works on Buxton Street, just south of what is now Piccadilly station, but earlier papers suggest a works at Oxford Works, Bridgewater Street.

Thompson’s must have been painfully aware of the advances coming from Germany with the Heidelberg debut in 1913, and production ramping after World War I. That advance was enormous. For the first time smaller printers doing ‘jobbing work’ no longer had to hand-feed their presses — the task of picking up, laying in the press, and picking out the printed sheets.

An Early Model of the Thompson Platen?

There’s some cloudiness over the beginnings of the Thompson press. The British Printer for October and November 1931 includes an advert for the automatic press and I’ve been contacted by a then-apprentice, Bernard Bennett, to say he used a very early Thompson in the 1940s. These were essentially a facsimile of the Heidelberg platen and an apparent patent battle led to these original Thompsons being recalled and destroyed.

The Sevenoaks Chronicle and Kentish Advertiser for 28 October 1932 includes a description of their new press installed following a fire at their works —

One of the smaller new machines Installed after the fire which destroyed the “Courier” last June is working at Stand 8: it is a “Thompson-British” auto platen with automatic feed, which can deliver printed sheets at the rate of 3,500 an hour. Although but a unit of the up-to-date machinery in the temporary works, it illustrates the perfection achieved by modem printing plant, and gives an idea of what the equipment of the Courier model new works will be like.

Sevenoaks Chronicle and Kentish Advertiser

So it would seem that by the early 1930s Thompson was offering a capable, automatic platen under their name.

The Post-War Thompson

Thompson secured a number of patents in the 1930s, with one in 1931 covering the ‘toggle mechanism‘ which transfers pressure to the platen; one in 1935 relating to the grippers that grab the paper; a 1937 patent to do with ‘sheet delivery‘; two in 1938 and one on inking in 1939.

It appears that these improvements, plus the impact of earlier legal action, gave us the familiar model of Thompson seen today, likely ready to manufacture at the start of World War II but interrupted by war. Mark and Graham Pressman relay that a family member of Thompsons reported that the Buxton Street factory was used for war purposes, rather than printing machines, during World War II.

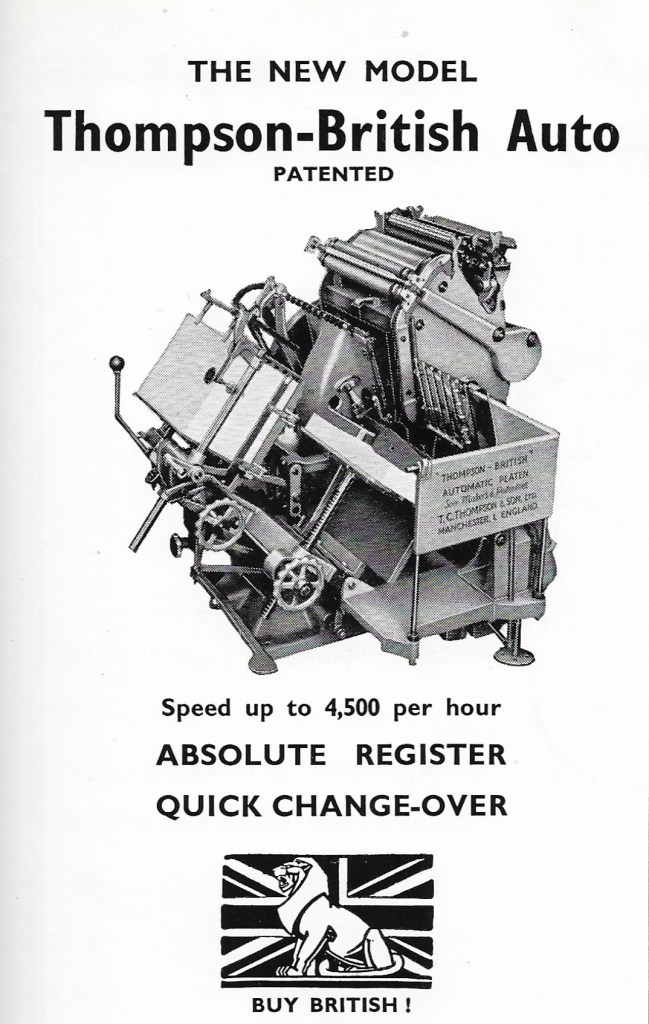

Production appears to have been shared between Buxton Street in Manchester and Alvis in Coventry. A deal brokered by the Ministry of Supply meant that the demand for these presses could be met by using these two factories. The Coventry Evening Telegraph reported that on 01 June 1948 the first machine to roll off the Alvis production line had been demonstrated. 2,500 special jigs, gauges and special tools had been crafted to be able to make the press in Coventry with a planned output of 1,500 presses each year.

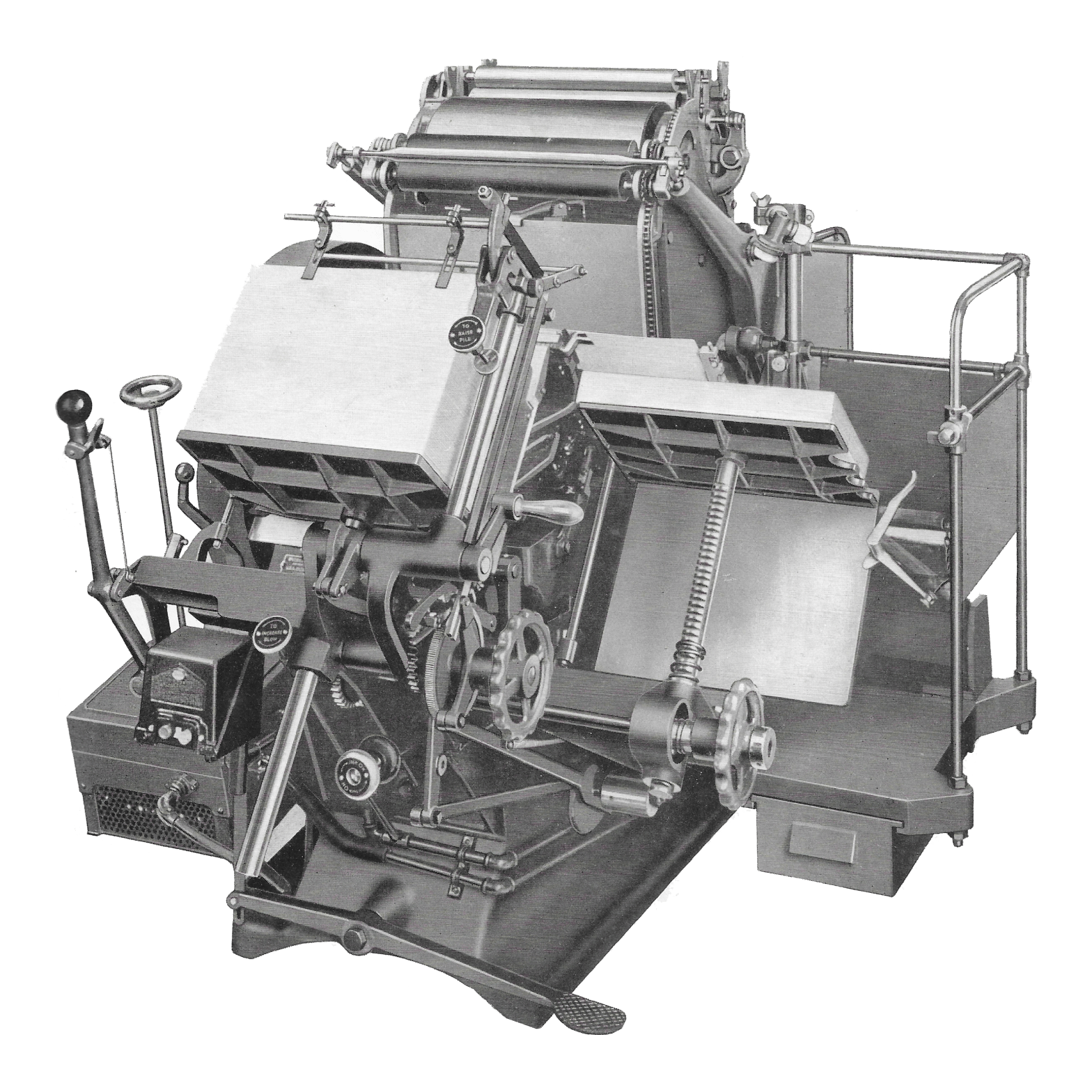

Features of the Thompson-British Auto Platen

There are two key things that supporters say mean the Thompson beats the Heidelberg. First, the way in which paper is handled — not being spun around like the ‘windmill’ — means that handling of paper stock is unparalleled. Publicity showed that 0·04mm (bank) to 0·94mm (board) paper could be automatically fed.

Secondly, the rollers had no chance to skid as they moved across the platen because the Thompson employed cogs at the end of each roller that meshed with a static chain down one side of the platen.

Testimonials from Holland stated “…The satisfaction exceeded our expectations; particularly the feed and delivery. We consider this a great improvement on the…(German machine).”

| Thompson-British Auto Platen | |

| Inside Chase | 15¼″ x 10½″ |

| Maximum Running Speed | 3,500iph, with the 1941 model offering 4,000iph |

The End of Thompson

It’s not clear at all when the link with Alvis in Coventry ended, but Thompson’s still continued in to the 1980s. Indeed in 1972 they secured a further patent for paper feeding for printing machines.

Christopher Lee contacted me in January 2009 to say he was one of the last people to leave the Buxton Street works in 1986. By that point the presses were being assembled by Albert and Roy in batches of two. Once the batch was complete the pair of machines would be inspected by Jack before being shipped. The building was sold shortly after with the spare presses and parts being sold to a firm in Birmingham.

Year and Era

1931 / Commercial

Object Type

Press

Location

Buxton Street, Manchester

Sources and More Information

- Bernard Bennett email, April 2008

- Christopher Lee email, January 2009

- Graham Pressman, Catseye Press

An Appeal

If you have something linked to this object, please get in touch.